Stamp concrete floor materials

-

Stamp concrete

Stamp concrete floor designs

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

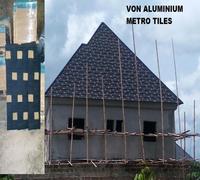

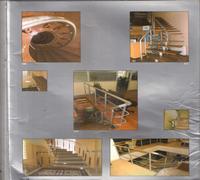

Stamped Concrete Floor Materials: A Durable and Decorative Flooring Solution

Stamped concrete floors have emerged as a popular choice for both indoor and outdoor applications due to their durability, affordability, and aesthetic versatility. This flooring technique involves imprinting patterns into freshly poured concrete to mimic the look of materials like brick, stone, slate, or wood. The success of stamped concrete floors hinges on the quality and compatibility of the materials used. Here's an overview of the key materials involved in stamped concrete flooring and their functions.

1. Concrete Mix

At the core of every stamped concrete floor is the concrete itself. The mix typically contains:

Portland Cement - The binding component that holds the mix together.

Aggregates - Sand and gravel that provide strength and bulk.

Water - Essential for hydration and workability.

The concrete must have the right consistency and set time to allow for stamping before it hardens completely. Depending on the application (e.g., residential patios vs. commercial driveways), different grades of concrete may be used.

2. Coloring Agents

To achieve the natural appearance of stone or other materials, coloring agents are added to the concrete. These include:

Integral Color - A dye added directly into the concrete mix, giving it a consistent color throughout.

Color Hardeners - Dry powders broadcast onto the surface of freshly poured concrete to add rich, concentrated color and increase surface strength.

Release Agents - These are powdered or liquid agents applied before stamping to prevent the stamping tools from sticking. They often contain secondary coloring pigments that give the floor an antiqued or textured look.

3. Stamping Mats and Tools

Stamping mats or skins are specialized tools made from polyurethane or other flexible materials. These are pressed into the surface of the concrete to create realistic textures and patterns, such as:

Slate

Cobblestone

Brick

Wood plank

Flagstone

Each pattern comes with various mats to ensure a natural, non-repetitive look.

4. Sealants

After the concrete has cured and been cleaned, a sealant is applied. This enhances the color, adds a slight sheen, and protects the surface from:

Moisture

UV rays

Chemicals

Wear and tear

Sealants can be water-based or solvent-based and are available in matte, satin, or glossy finishes.

5. Optional Additives

In some cases, contractors may use additives to modify the concrete's performance:

Retarders - Delay the setting time, giving more time for stamping in hot climates.

Accelerators - Speed up the curing process in cooler conditions.

Plasticizers - Improve workability without adding excess water.

Benefits of Stamped Concrete Flooring

Aesthetic Appeal: Mimics high-end materials at a lower cost.

Durability: Withstands heavy traffic and weather extremes.

Low Maintenance: Especially when properly sealed.

Customizable: A wide range of patterns, colors, and finishes.

Conclusion

Stamped concrete flooring is an excellent blend of function and design. By carefully selecting quality materials--from the base concrete to the sealants--homeowners and builders can achieve long-lasting, beautiful surfaces that elevate the look and value of any space.