QT12-15 Automatic Brick Making Machine

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

QT12-15 Automatic Brick Making Machine

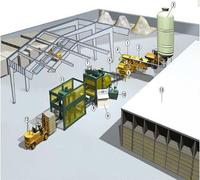

Descriptions of QT12-15 Automatic Brick Making Machine:

1.QT12-15 automatic block making machine has the production output of 17280-23040 blocks (400×200×200mm) for one day (8 working hours).

-- 12 stands for the production quantity is 12 blocks "400×200×200mm" per mould;

-- 15 stands for the cycle time is 15 seconds

2. As the moulds are changeable, QT12-15 is able to produce various types of hollow blocks, solid bricks, interlocks, pavers and curbstones, etc.

Main Technical Specifications of QT12-15 Automatic Brick Making Machine:

| Production per Mould | 12 pcs/mould (Standard Block: 400×200×200mm) |

| 60 pcs/mould (Solid Block: 240×115×53mm) | |

| 35 pcs/mould (Hollow Block: 240×115×90mm) | |

| 48 pcs/mould (Holland Brick: 200×100×60-80mm) | |

| Cycle Time | 15-20 seconds |

| Production per Day (8 Working Hours) | Hollow Block (400×200×200mm): 17280-23040 pcs |

| Solid Block (240×115×53mm): 80640-115200 pcs | |

| Hollow Block (240×115×90mm): 50400–67200 pcs | |

| Holland Brick (200×100×60-80mm): 55296–69120 pcs | |

| Vibrating Frequency | 2940 rolls/minute or 50-65 HZ |

| Vibrating Force | 160 KN |

| Motors Power | 64 KW |

| Machine Dimensions | 9100×4800×3170mm |

| Pallet Size | 1400×1000×30mm |

| Gross Weight | about 15T |

| Raw Materials | Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

| Applicable Products | concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applicable Fields | widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

Main Features of QT12-15 Automatic Brick Making Machine:

1. Uses Germany Siemens PLC control system and Siemens Touch Screen.

A. Visualization screen with easy operation;

B. Is able to set up, update and amend the production perimeters, to maximize the production output;

C. Dynamic display of the system's status, automatic trouble shooting and warning notice;

D. Has automatic-locking function, avoiding mechanical accidents caused by operational mistakes;

E. Is able to troubleshoot the machinery via teleservice.

2. Uses high-dynamic proportional and directional valves, which automatically adjust the oil flow and pressure as per specific working requirements, to buffer the hydraulic cylinder when working; uses integrated high-pressure and soft oil pipes, with easy installation;

3. Uses airbag cylinder to reduce the vibration shaking;

4. Uses multi-shaft rotating and compulsory feeding, which greatly improves the density and intensity of the blocks, and reduces the feeding time as well;

5. Integrated structure of vibrating and moulding platforms, which reduces the weight of the machine, and improves the vibrating efficiency;

6. Uses one single motor to drive the vibrator via transmission shaft, avoiding the inconsistency of double motors, so as to save the power;

7. Uses double-line aero vibration-proof system, which reduces the vibrating force on the mechanical parts, improves the using lifetime of the machine, and reduces the noise;

8.High-precision guide bearings are used to assure the precise movement between the tamper head and the mould;

9. Heavy-duty machine frame, which uses high-intensity steel and advanced heat treatment, is wear resistant.