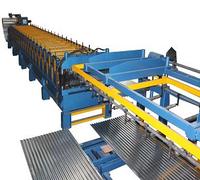

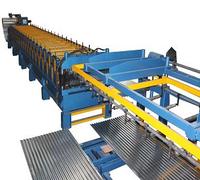

Aluminium / Steel Stepped Roofing Ridge Cap Corrugated Sheet Roll Forming Machine

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

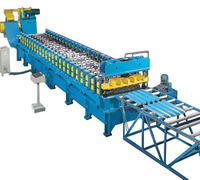

Automatic Steel & Aluminium Stepped Roofing Ridge Cap Roll Forming Machine With Mitsubishi PLC, Inverter and Operator

Introduction

This metal colld roll former machine is making stepped roof ridge cap sheets. The surface of finished ridge capping sheets is smooth and without any scratch. We adopt Mitsubishi PLC control system for the machine and the parameters like sheet length, sheet quantity can be set into the control system through touching screen, then this roll former machine will start the prodcution automatically. We usually design and manufacture the machines according to customers' requirement.

Machine Features:

1. Precise Forming

2. High-solid forming stand guarantees a good and uniform high quality of final products

3. The operation automatically minimizes the tolerance of cutting length

Technical Parameters of Steel & Aluminum Roofing Ridge Cap Panel Rollformer:

Material Spec: Colored and galvanized steel sheet, aluminum sheet, 235MPa

Thickness of Coil Sheet: 0.4-0.7mm

Coil Width: It's up to the final ridge cap design

Working Speed: around 3m/min.

Main Motor Power: 5.5KW

Hydraulic Station Power: 5.5KW

Passive Uncoiler: max. capacity 3 tons

Quantity of Stands: around 15 groups

Controlling System: Mitsubishi PLC

Type of Cutting: Roll-Formed and Length-Set Cutting

Total Weight: About 7.5 tons

Voltage: 380V/3 phase/50 Hz or designed according to customers' requirement

Main Components of Metal Roof Ridge Cap Production Line

3 Tons Uncoiler 1 Unit

Direction Guilder 1 Unit

Roll Former Machine 1 Unit

Step Presser 1 Unit

Cutting Device 1 Unit

Mitsubishi PLC Controller 1 Unit

Conveyors 2 Units

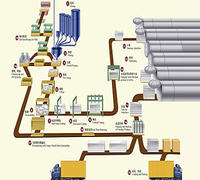

Working Flow:

Decoiling---->Sheet Guilding---->Rollforming---->Cutting---->Finished Ridge Caps on Conveyor

Aluminium / Steel Stepped Roofing Ridge Cap Corrugated Sheet Roll Forming Machine

Application: The finished step ridge cap is recommended to prevent water, rain or snow leakage for industrial and residential applications with simple installation. Ridge-stepping on cap is to match with step tile.

We are supplying all kinds of oven baked aluminium roofing sheets making machines, such as box prfiled longspan metral roofing sheet making machine, normal steptile roof sheet making machine, metcopo step tile roof sheet making machine, cameroon aluzinc roof sheet making machine, ridge cap manufacturing machine and so on. If you want to get more details about this Aluminium / Steel Stepped Roofing Ridge Cap Corrugated Sheet Roll Forming Machine, please contact us by the following information!

Email: [email protected]

Mobile: +0086 158 6814 2550